UVLED curing machines are widely used in medical equipment, optics, optical communication, liquid crystal, printing, coatings and other industries. Compared with traditional curing methods, curing is faster, more efficient, energy-saving and environmentally friendly. What factors affect the deep curing of UVLED curing machine?

UV coating thickness

The thickness of the UV coating has an effect on both curing and bonding. If the coating is too thick, the drying time under the same power light source will be relatively long, and the surface temperature of the substrate will be too high, resulting in deformation of the substrate. If the coating is too thin, it will result in poor gloss on the surface of the product.

curing distance

The curing distance is the irradiation height of the UVLED light source. The curing distance needs to be adjusted appropriately with the irradiation power of the substrate, coating and UVLED curing lamp. Generally, the distance of ordinary UV curing is about 10mm-15mm, and the curing distance of ink is generally less than or equal to 5mm.

UVLED energy

For UV coatings to be able to cure deep, the main condition is that the molecules must absorb enough energy. Only in this way can the unsaturated organic compounds in the UV coating undergo chemical reactions such as polymerization, grafting, and cross-linking to achieve the purpose of curing. It is also important to choose a UVLED curing machine with uniform illumination and stable performance.

Curing speed

The effect of curing speed on UVLED curing is also there. If the curing speed is too fast, the UV coating on the surface of the substrate will be sticky or the interior will not be cured. A slow curing rate will cause the surface of the substrate to deteriorate.

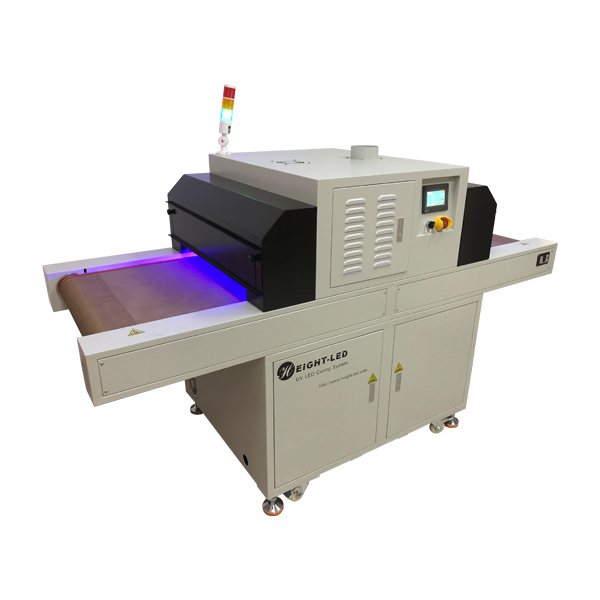

As a manufacturer of UVLED curing equipment, Shenzhen Height-LED is committed to providing customers with a complete set of curing solutions. The products have standard products and can also customize products according to customer needs. If you have UVLED curing requirements, you can contact online customer service, or call for consultation and exchange.